200W 300W MOPA Metsi a Pholisa Laser ea ho Hloekisa Mochini

Likaroloana

1. Software e bonolo, khetha li-parameter tse bolokiloeng ka ho toba

2. E bolokile mefuta eohle ea litšoantšo tsa parameter, mefuta e tšeletseng ea litšoantšo e ka khethoa: ho tlatsoa ka selikalikoe / spiral / selikalikoe / khutlonnetsepa / khutlonnetsepa.

3. Ho bonolo ho e sebelisa le ho sebetsa

4. Mefuta e fapaneng ea 12 e ka fetoloa le ho khethoa kapele ho tsamaisa tlhahiso le ho lokisa liphoso

5. Puo e ka ba ea boikhethelo, Senyesemane / Sechaena kapa lipuo tse ling (haeba ho hlokahala)

6. Mochine o hloekisang oa laser o kopane haholoanyane ho rala ka boholo bo fokolang le boima bo bobebe.

7. 'Mele oa mochine o hloekisang oa laser o entsoe ka boleng bo phahameng ba tšepe ea tšepe' me likarolo tsa bohlokoa tsa ts'ehetso li matlafatsoa bakeng sa ho tšoarella haholoanyane.

Kopo

1. Sebakeng sa tlhahiso ea indasteri, lisebelisoa tsa mechine li 'nile tsa sebetsa ka nako e telele,' me palo e kholo ea oli, pente ea litšila, mafome le li-deposit tsa carbon li bokelletse holim'a likarolo le likaroloana.Theknoloji ea ho hloekisa ka laser e ntlafatsa haholo phello ea carbon deposition le boleng ba ts'ebetso ea welding.E ka hloekisa ka nepo ho beoa ha k'habone holim'a li-substrates tse fapaneng, ea fokotsa mefokolo ea welding, le ho ntlafatsa ho cheseha ha thepa;ka nako e ts'oanang, e ka boloka litšenyehelo tsa tlhahiso ea khoebo, ho ntlafatsa katleho ea tlhahiso ea khoebo.

2. Sebakeng sa ts'ebetso ea microelectronics, polyimide ke thepa ea dielectric bakeng sa mohaho oa ka hare oa ho kopanya oa lifilimi tsa liphutheloana tsa elektronike.

3. Indasteri ea mechine e nepahetseng hangata e hloka ho tlosa li-ester le oli ea liminerale tse sebelisetsoang ho tlotsa le ho thibela ho bola likarolong, hangata ka mekhoa ea lik'hemik'hale, 'me hangata ho hloekisa lik'hemik'hale ho ntse ho e-na le mesaletsa.Laser degreasing ka tlosa ka ho feletseng esters le oli ea diminerale ntle le ho senya bokaholimo ba likarolo.

Mekhahlelo

| Lebitso la parameter | Boleng ba paramethara |

| Mofuta oa laser | Nanosecond pulse fiber ea lapeng |

| Matla a phahameng a tsoang (W) | 200/300 |

| Bohareng ba wavelength (nm) | 1064±5 |

| Lethathamo la taolo ea matla (%) | 10-100 |

| Ho se tsitse ha motlakase (%) | ≦5 |

| Ho se tsitse ha matla a tsoang (kHz) | 10-50/20-50 |

| Pulse length (ns) | 90-130/130-140 |

| Boholo ba matla a ho otla ha pelo (mJ) | 10/12.5 |

| Bolelele ba fiber e tsamaisang (m) | 5 kapa 10 |

| Sehlopha sa tšireletso ea laser | 4 |

| Mokhoa oa ho pholisa | pholiso ea metsi |

Mehaho

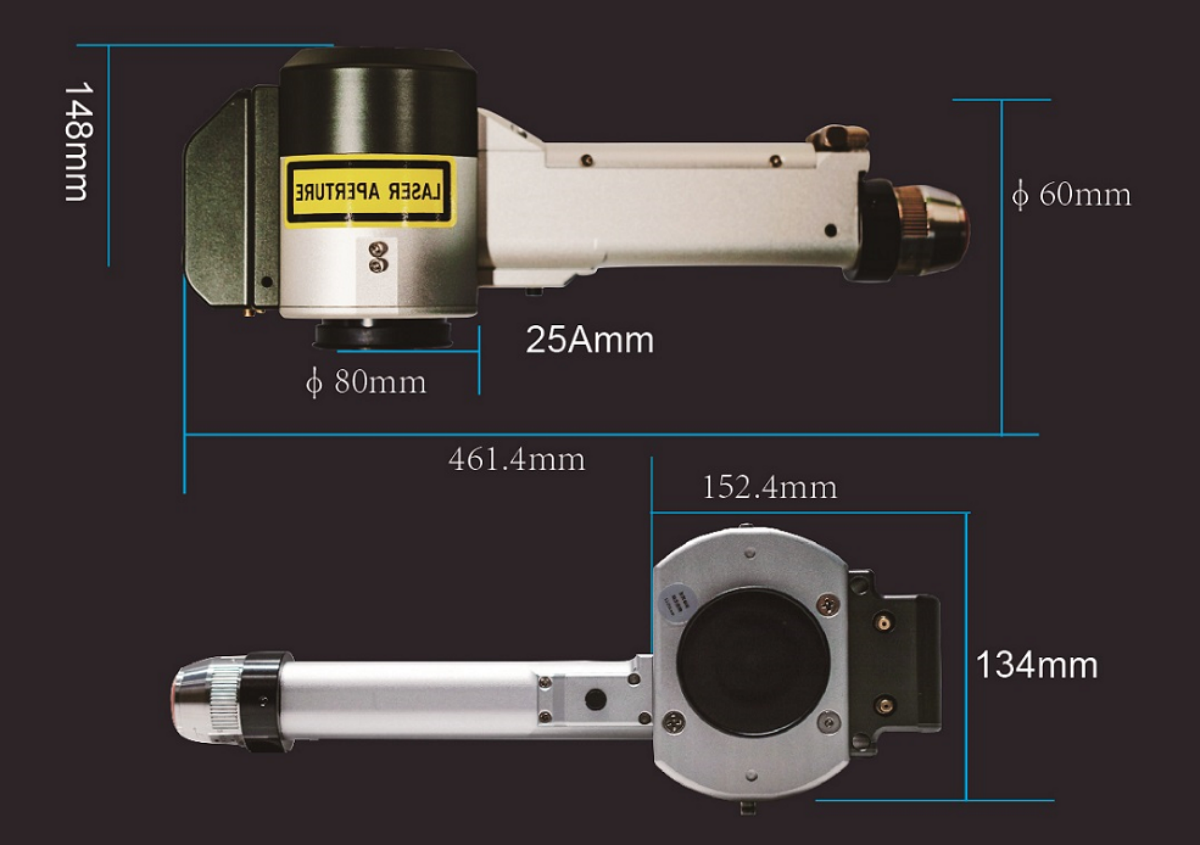

Boholo ba hlooho ea ho hloekisa ka laser: